CNC Machining Center

High-precision computer-controlled machining equipment

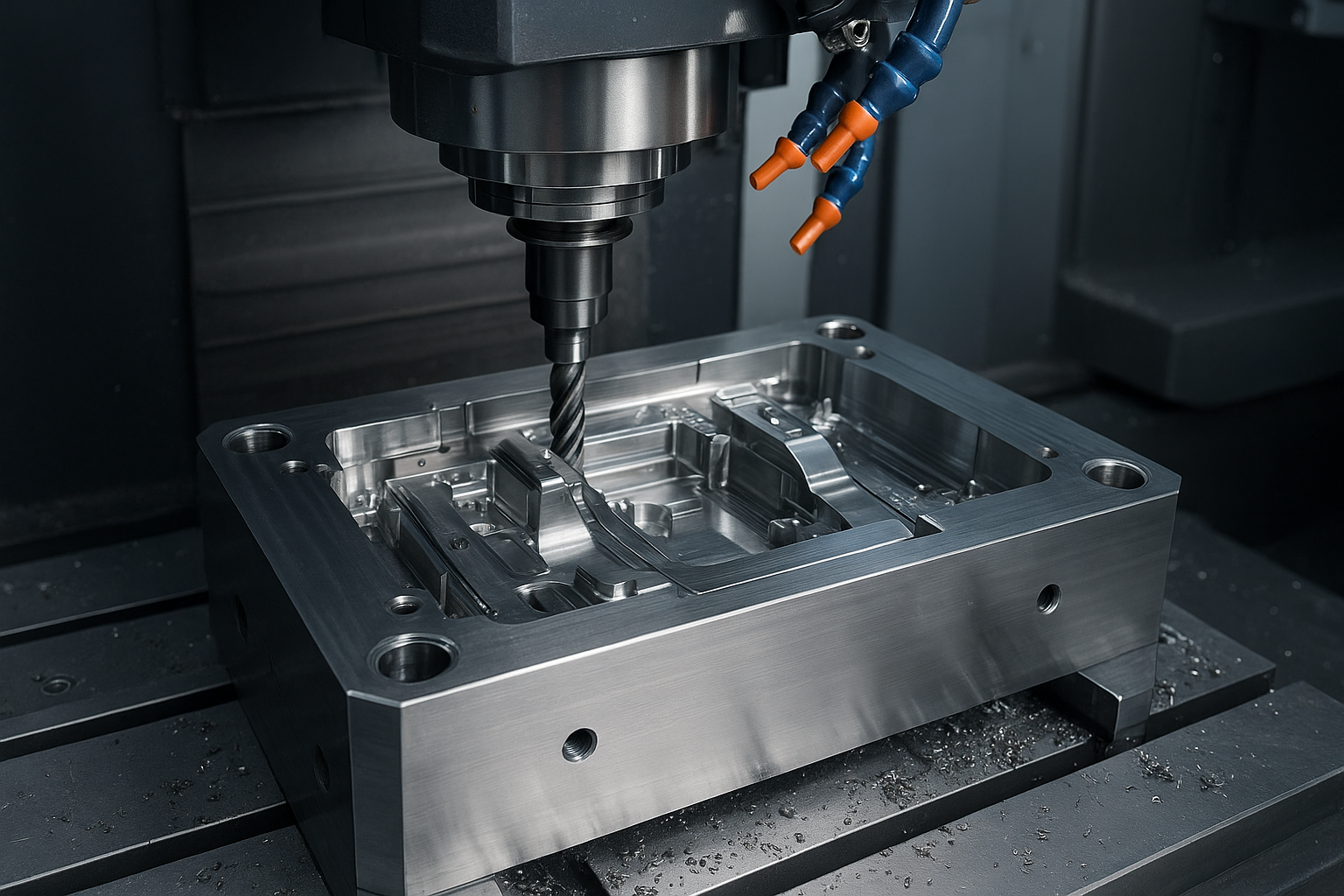

5-Axis CNC Machining Center

Advanced 5-axis simultaneous machining for complex geometries and contours.

3-Axis Vertical Machining Center

High-speed vertical machining for precision components and mould bases.

CNC Turning Center

Precision turning with live tooling for complex rotational parts.