Our Story

Four decades of engineering excellence and innovation

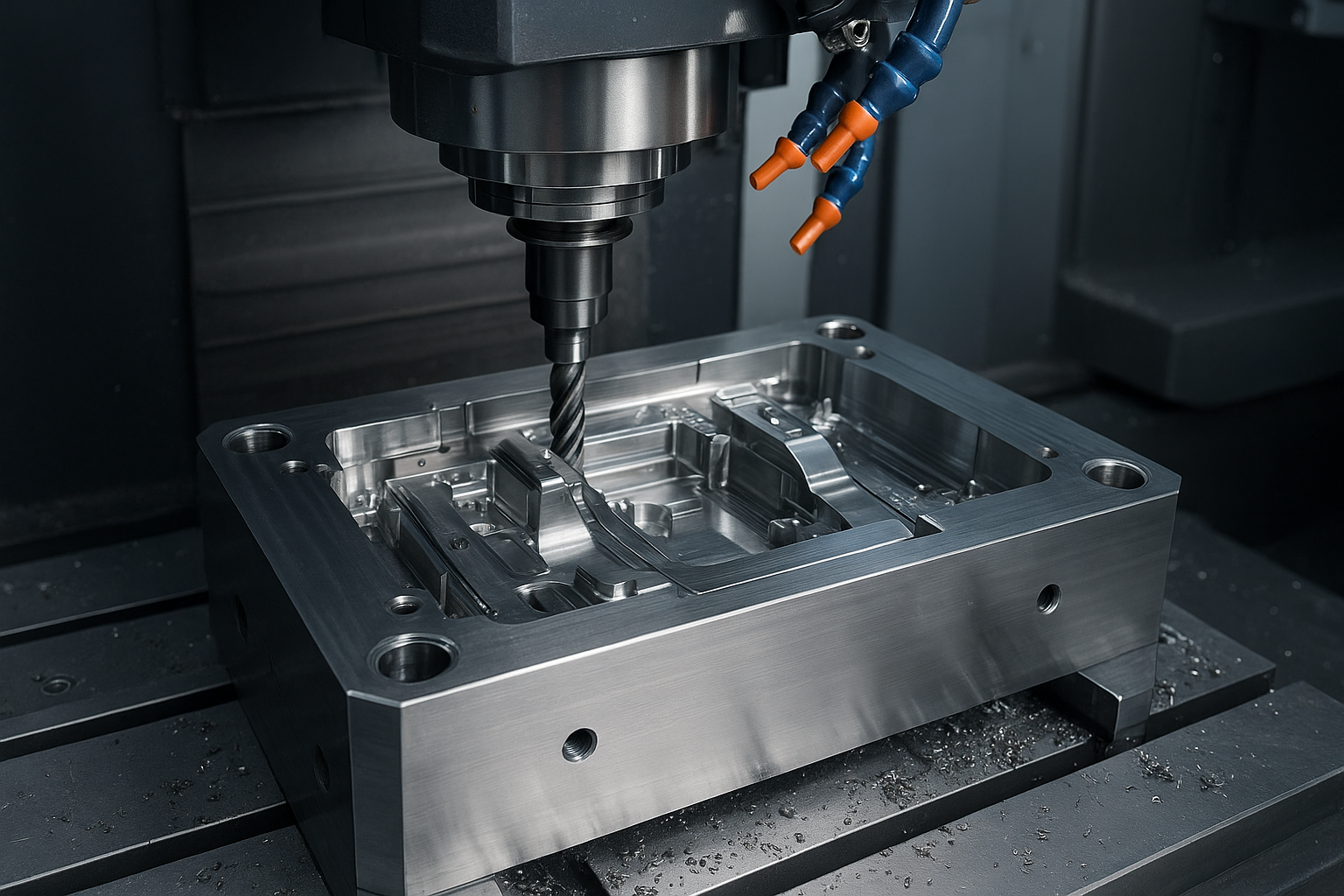

Founded in 1983, Neil Engineering Components began as a small workshop with a single hand-injection press and a vision for precision engineering. Over the decades, we've evolved into a comprehensive manufacturing partner for industries worldwide.

Our journey reflects our commitment to innovation, quality, and customer satisfaction. From manual craftsmanship to digital automation, we've maintained the same dedication to excellence that defined our beginnings.

Read Our Full Story